How to Draw Out Shop Plans for Warehouse

Devising a warehouse's layout is the showtime step in designing an installation. While this may seem similar a unproblematic issue, in practise it is difficult to figure out. In this article, it outlines the main factors that need consideration in the design procedure. Equally well, it shows an example of a warehouse layout distributed into 6 differentiated areas, including AS/RS systems.

Generally speaking, warehouse designers accept to work with a space in which certain factors limit the surface area available. This is why the layout has to exist advisedly planned. When deciding on the internal and external layout of a warehouse, at that place are iii possible scenarios that could necessitate a different assignment of space: the installation of new warehouses, the extension of existing facilities and the reorganization of those currently operating (even though the last of these options does non involve making extremely important decisions that will affect the development of the business concern over the medium- to long-term).

However, despite the specific circumstances, the general layout of a facility must cover all these needs:

- Making the near of the bachelor space

- Reducing the treatment of appurtenances to a minimum

- Providing easy access to the stored production

- Having the highest rotation ratio possible

- Offering maximum flexibility in the positioning of products

- Decision-making the amounts stored

To attain these objectives, the first stride is to create awarehouse layout, where the design of the warehouse is represented in the form of a plan.

First and foremost, the created layout must respect the bones rules of good storage mentioned above and avoid areas and points of congestion, facilitate maintenance tasks and establish the resources required to obtain the greatest possible workflows, with the associated reduction in runtimes.

The following areas must be perfectly defined when designing a layout:

A. Loading and unloading areas

B. Reception area

C. Storage area

D. Picking area

E. Dispatch area

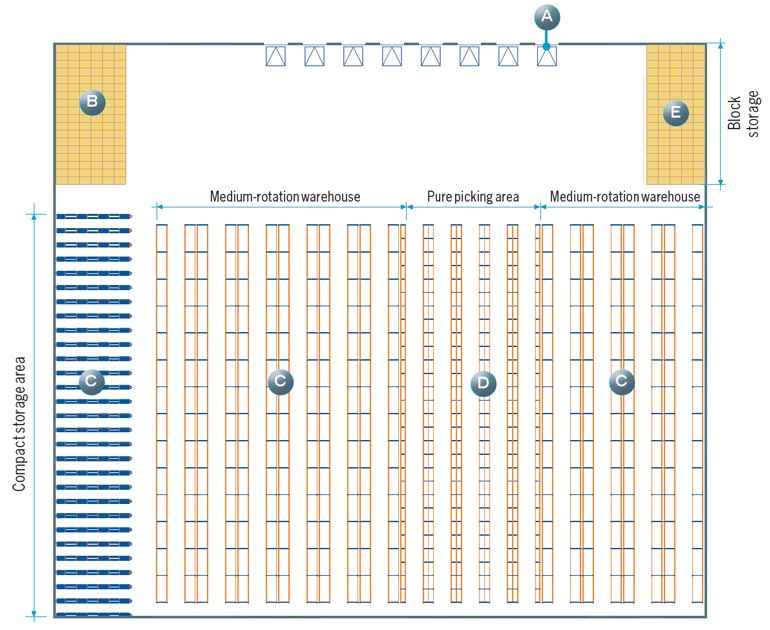

An instance of a layout that includes all of these areas is shown below:

Loading and unloading areas (A)

Loading and unloading areas, which are normally located outside the warehouse or incorporated into information technology, are those that trucks and vehicles transporting and distributing goods have direct access to.

In a well-organized warehouse, information technology is useful to separate these activities from the remainder of the installation, assuasive sufficient space for loading and unloading. This area can exist integrated into the warehouse or be independent.

Dock with platform attached to a warehouse

Dock with intermediate platform in a common cold storage installation

Loading and unloading areas integrated into the warehouse

If loading and unloading areas are congenital directly into the sides of the warehouse and then that goods are deposited and collected without the need for whatever detours, it is said that they are integrated into the facility. The main advantage of this is the greater load handling speed, which ways it is preferable to non-integrated options if at that place is sufficient space for it.

Trucks are connected to the warehouse via the docks and these docks can exist:

- Docks separated by an intermediate platform: They are appropriate when this separation is advisable every bit determined by the nature of the goods or the demand to maintain the internal warehouse environment or when at that place are safety issues relating to the material stored. A typical example of applying this blazon of separated dock is for common cold chambers, where cold loss could occur if a flush dock is used with an access door and where this must be avoided at all costs. Yet there are many other circumstances in which this design is preferable, especially when the safety of the warehouse could be compromised.

- Affluent docks: They let trucks to dorsum correct up to the warehouse wall. To avoid affecting the internal surroundings of the facility, access doors must take, as a minimum, a hermetically sealed arrangement. This seal can be metal or created through the utilise of a dock shelter.

Docks with directly access to the inside of the warehouse

Access points with metallic seals have a manual or automated organisation that operates a flat bulwark that tin can be fixed, folding, or rolling (as shown beneath). It opens when the truck backs up to the building, and closes when the vehicle has finished the operation. The internal environment can be more than effectively preserved if the endmost system is automated.

In addition to a metal seal, doors with inflatable shelters have a tunnel that encircles the truck when information technology is continued to the entrance, and so that the internal environment is less compromised by conditions outside.

Door with an inflatable shelter.

Exclusive door.

Roll-upwards door.

When this type of loading area is created, it is advisable for the warehouse floor to be above the level of where the trucks drive. Loading and unloading areas can besides exist designed in which trucks are driven into a pit. However, movement and operations are faster if the warehouse is at a higher level instead.

The necessary top difference can be achieved in several ways; therefore, it is not vital for the warehouse floor to be higher up ground level. Instead, for example, the surface area where trucks drive tin can be at a lower level, creating a gradual descent that avoids the steep ramps which, ultimately, make maneuvers more difficult and wearisome down movement.

View of a dock in a pit.

Two different scenarios need to be considered when determining how to achieve this height deviation. The start is when trucks accessing the loading and unloading areas are owned past the company. The 2d is when the trucks used are endemic by 3rd parties.

If simply the company's own trucks are going to use the loading and unloading areas, and the meridian of the trailer is exactly the same in each case, the divergence in level can be established precisely and no further considerations are required.

However, if the trucks that are going to access these areas are owned past third parties and come from different sources, they will have dissimilar trailer heights. So, a system must exist created that allows the difference in height to be adjusted.

Pallet truck.

In general, an adjustable leveler system is essential considering fifty-fifty when the company uses its own fleet, which in theory means there is no variation in the superlative deviation between the vehicles and the dock. In practice, this departure is always present.

One of the reasons for this is the suspension in the trucks give way over fourth dimension, either because different loads cause the tiptop of the truck to vary or, more than normally, because eventually the company is obliged to buy or lease other types of transport. Ultimately, a difference in trailer heights is practically inevitable.

Mechanical or hydraulic devices can be used to deal with these tiptop differences. Mechanical devices are based on the employ of (usually metal) bridges or walkways fitted manually between the dock and the truck.These elements are used so that forklifts, stacker cranes, and any other mechanical devices used to load and unload trucks tin enter and exit the vehicle.

Another choice is to use the 2nd arrangement mentioned to a higher place, which consists of a metallic platform with 1 or more hydraulic cylinders. This platform facilitates access by acting every bit a ramp,when integrated into the dock itself, or past raising and lowering the truck. The image illustrates the second option, with the platform integrated into the dock.

Single platform.

Integrated platform.

Independent loading and unloading areas

Located abroad from the warehouse, but inside the surrounding area, they operate completely independently of the warehouse itself. They normally consist of a large flat expanse that the trucks have direct access to, with the trucks positioned so that they tin can exist loaded or unloaded using forklift trucks.

This option is best used in warehouses where just 1 of the two functions is carried out, i.e. where goods are loaded or unloaded. This choice

tin achieve the necessary handling speed, as there is no need for the trucks to support to the edifice. So, the fourth dimension spent positioning them is reduced. In addition, with this option the procedure of loading and unloading goods is totally independent of the work bike of the warehouse.

In these areas, goods in the trucks can exist handled through the side or the rear of the vehicle. If using the side of the vehicle, forklift trucks are used to handle the appurtenances, as shown in the epitome below.

Forklift handling the goods from the side.

Ramp access.

If, withal, the operation is carried out using the rear of the truck as shown above, at that place are two different options. The first is to access the truck using forklift trucks and ramps, which are ordinarily made from metallic and connected to the truck either manually or mechanically. While in that location is a broad choiceof such products available on the market, at the moment ii are most unremarkably used: modular ramps and those continued to the unloading docks.

Modular ramps are metal structures with a non-slip surface which can either be fixed (when the trucks used are all of the same height) or mobile (when using vehicles of different heights).

Ramps connected to the unloading docks are made with a brick or physical construction, which can as well be fixed or variable in acme. If variable, their construction is like to that of the integrated loading and unloading docks described previously.

The second option for the loading or unloading trucks by the rear is to use roller conveyors.With this system there is no need for the forklift to enter the trailer to acquit out the operations. Instead, rails are installed which let goods to slide along the within of the truck. Movement is generated by pushing a few loads against other ones.

Automated loading using sliding elements.

The loading procedure starts by placing one or more units at the entrance to the vehicle, which are then pushed in by a second grouping that takes the place previously occupied by the commencement group. In this way the loads accumulate, ane after some other, until the trailer of the truck has been filled.

Reception expanse (B)

The reception area must be located as independently as possible from the rest of the warehouse, so that it can be used not just for receiving appurtenances, only also for quality-command and sorting.

Reception surface area.

Once it has been ensured that the characteristics and quality of the delivery received matches those of the products ordered, the adjacent phase is to make up one's mind where to position the load inside the warehouse.

Depending on the type of warehouse, information technology may or may not exist necessary to transform the units received. If this is necessary, a suitable area must exist established for this function. For case, it may be necessary to split the pallets that take arrived into smaller units, remove parts that are strapped together, etc.

Given the impact that accurate checking and, above all, correct positioning, tin have on the future performance of the warehouse, this area must be as large and every bit dissever every bit possible.

Currently, almost all products handled in a warehouse come with barcodes that can be read using a scanner. Therefore, once the warehouse's key estimator has identified the units, information technology can in plow immediately generate the position label for the goods. This label tin later be read past a forklift operator or past the scanners of the warehouse's automated system so that, in both of these cases, they can be positioned in the correct location.

The RF device reads the coded data on the pallet.

Storage surface area (C)

A storage area is, strictly speaking, an area used only to store goods.

Goods can exist stored in a number of different ways: directly on the footing; directly on the ground but stacked or in blocks; or on racking units. The choice of one or the other volition depend in a higher place all on the blazon of product to be stored, whether information technology can be stacked, and on the storage quantity and time.

Storage in stacks involves placing unit loads on top of each other without anything in betwixt them, other than the pallets that support them. This method has the advantage of making better utilize of space, given that it does non generate unused positions. All the same, non all materials can exist stored like this and information technology must be remembered that fifty-fifty goods that can be stacked have their limits in terms of strength and, therefore, accept a maximum stacking pinnacle. The chief disadvantage of this arrangement is that it does not permit for access to the loads, and a load can merely be accessed by starting time removing all the loads on summit of information technology.

The use of stacking is mainly limited to two types of load: those with great internal strength, and those in rigid packaging. Goods with cracking internal forcefulness, such as ceramic bricks, concrete blocks, etc., can be stored directly, at times even without the need for pallets or other support systems. Other appurtenances, such equally feed, cements, and aggregates in general, which are stored in sacks, can also be stored in this manner thanks to their resistance to compression, although pallets or other support systems are required for their proper treatment.

Rigid packaging, such as cardboard, wooden or plastic boxes, tin can be stacked in this way without bug, although the rigidity and resistance of these packages volition make up one's mind the number of units that can be stacked, and therefore the pinnacle of the stack.

Racking units must be used when unit loads are non strong enough to be stacked to the required elevation, or when there is a greater need to access the production.

Appurtenances are stored on racking units past placing them on metal structures, which are basically made up of suitable braced frames and beams. These elements create a multi-cellular construction that generates slots into which unit loads tin can be placed. Every bit seen in "Storage systems" commodity, the configuration and layout of these spaces (or compartments) can vary to suit different operations and different needs in terms of the accessibility and accumulation of the load.

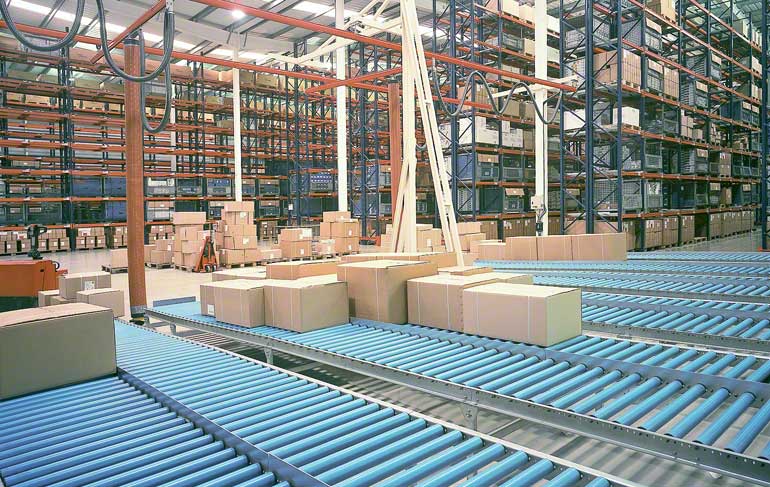

Warehouse of a distribution company.

Order picking areas (D)

These areas are non required in all warehouses, only when outgoing goods must have a configuration or composition that is dissimilar to the i they entered with, or when they require any type of modification.

Areas for preparing orders can be integrated into storage areas, as is the instance when picking from rack units. They can as well be separate from storage areas, creating specific picking areas, generally with automated or semi-automatic systems.

The image shows an club picking area in a warehouse for faucets and bathroom accessories.

Dispatch areas (E)

These areas are used for packing orders prepared in the previously described areas. Even if this packing operation is unnecessary, this area also can be used for goods that take to be dispatched and loaded into the delivery or distribution vehicles.

To ensure the right speed of movement inside the warehouse, these spaces must be designed in a specific location and differentiated from the rest of the installation.

If dissever reception and acceleration areas have been created, these must also have carve up loading and unloading areas. If, however, the reception and dispatch are close to each other, a single loading and unloading infinite can exist created. However, this pick makes it more difficult to control the menstruum of goods and the movement of vehicles.

Warehouse of a distribution company.

Service areas (F)

Part of the warehouse must be assigned to support activities at the facility, such as general and management offices, changing rooms, bathrooms, and the area for recharging the batteries of treatment devices.

The ideal solution is for the management office to be located in the reception and dispatch area and, if possible, betwixt these 2 areas. This provides greater operability and efficiency in the work of the personnel in this section.

Changing rooms, bathrooms, and general offices can be located anywhere in the warehouse, although it is more logical to locate these close to the control offices. A practiced solution for bringing together these resources is to construct a mezzanine over the reception and acceleration surface area, and to locate these functions at that place.

Lastly, the space for recharging the batteries used by handling devices must be isolated and well ventilated, to improve health and safety and avoid whatsoever incidents involving operations taking place in this area.

Source: https://www.interlakemecalux.com/warehouse-manual/warehouse-design/warehouse-layout

0 Response to "How to Draw Out Shop Plans for Warehouse"

Yorum Gönder